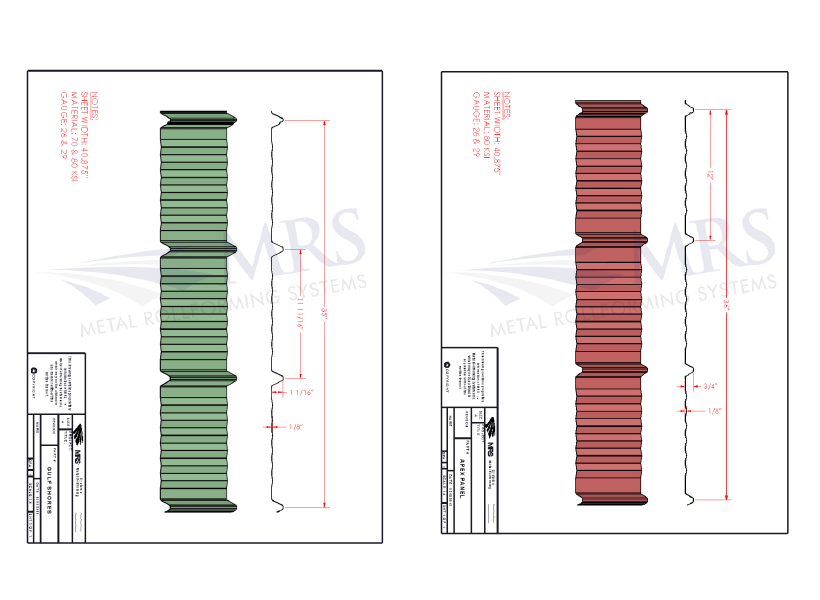

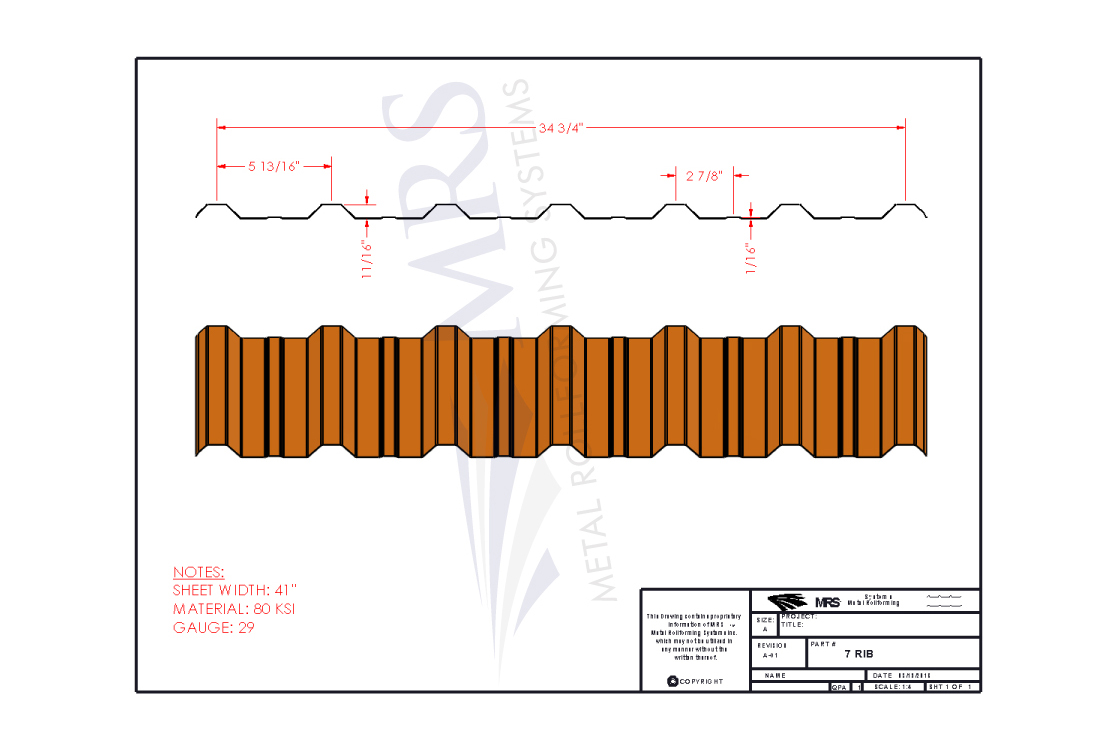

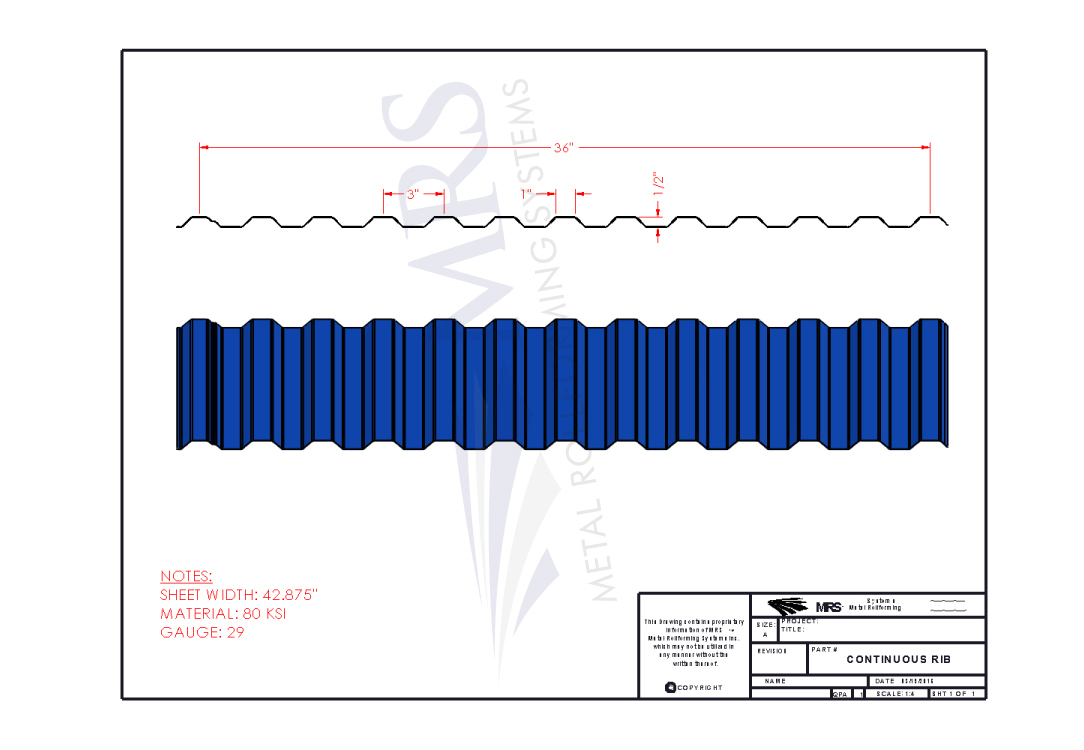

Custom Panel Profiles you can run with 29 ga, 40.875” material

One of the largest investments in Rollforming is inventory. The panel profiles in this category are excellent choices when trying to minimize inventory investment while maximizing profit margin. All of these profiles run the industry standard 29 gauge, grade 80, 40.875” material you most likely already stock for the “AG” panel. However, these panels are not a “commodity” market panel with downward pricing pressure. These panels give your customer a different architectural look allowing you to charge more AND differentiate yourself from the competition.

John B.

“I added the Gulf Shores panel on top of my MRS Signature line which was already producing the Tuff rib profile. After around 4 months of getting the word out to contractors, architects, and homeowners we started to see an increase in sales, not just in the Gulf Shores profile but also the Tuff rib as we were able to attract new contractor accounts because of the additional profile and versatility. We were also able to increase the price on the Gulf Shores profile by $.15 a lineal foot.”

The main advantages of the adding one of the profiles below, or designing your own custom profile are:

- Utilize existing inventory

- Increase market penetration

- Increase margin

- Differentiate yourself from your competition

The above profiles offer a similar look to a Snaplock profile and are increasingly popular in the residential marketplace. Installation time and costs are identical to a through-fastened panel and about ½ the labor cost of Snaplock. Combined with low profile fasteners customers have found these profiles to be big sellers to homeowners and contractors alike.

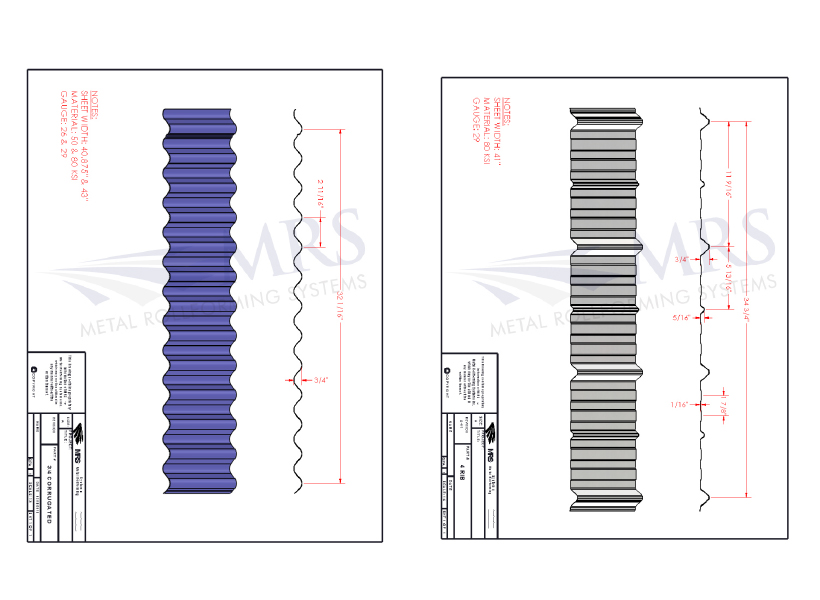

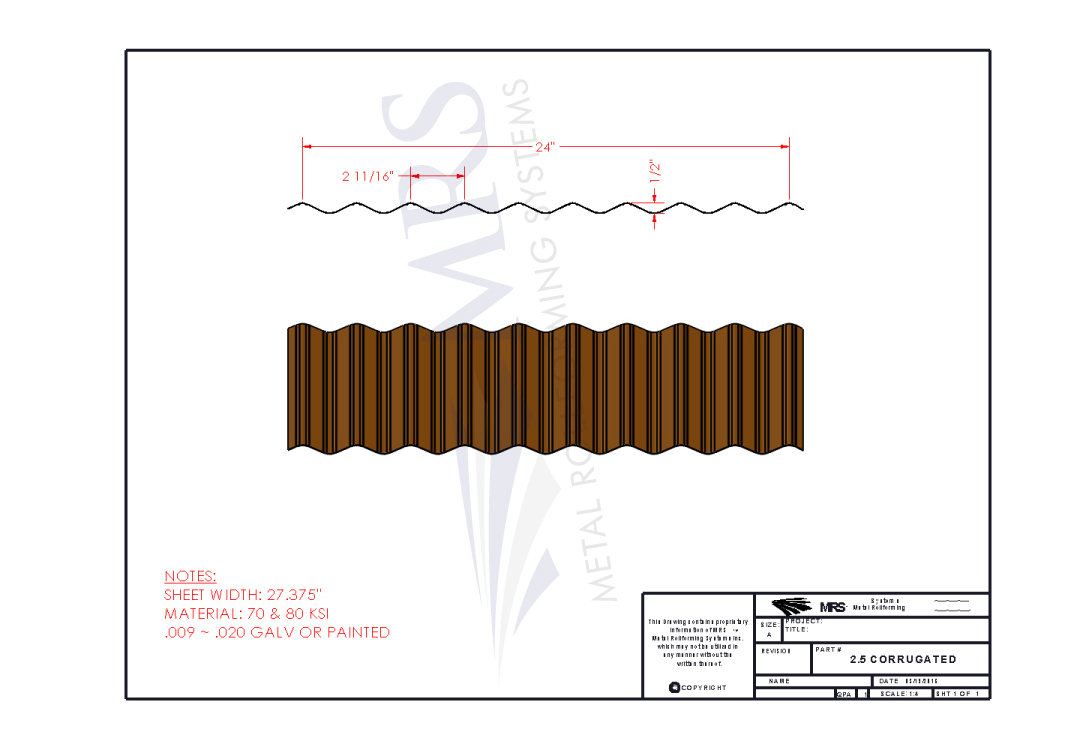

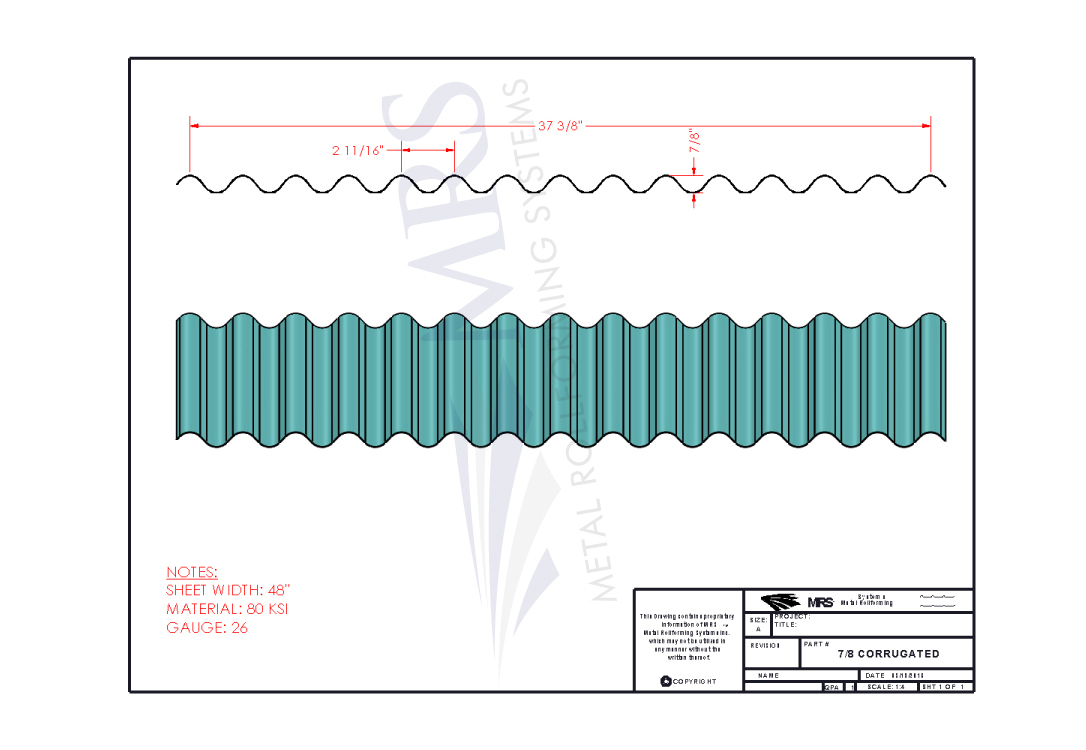

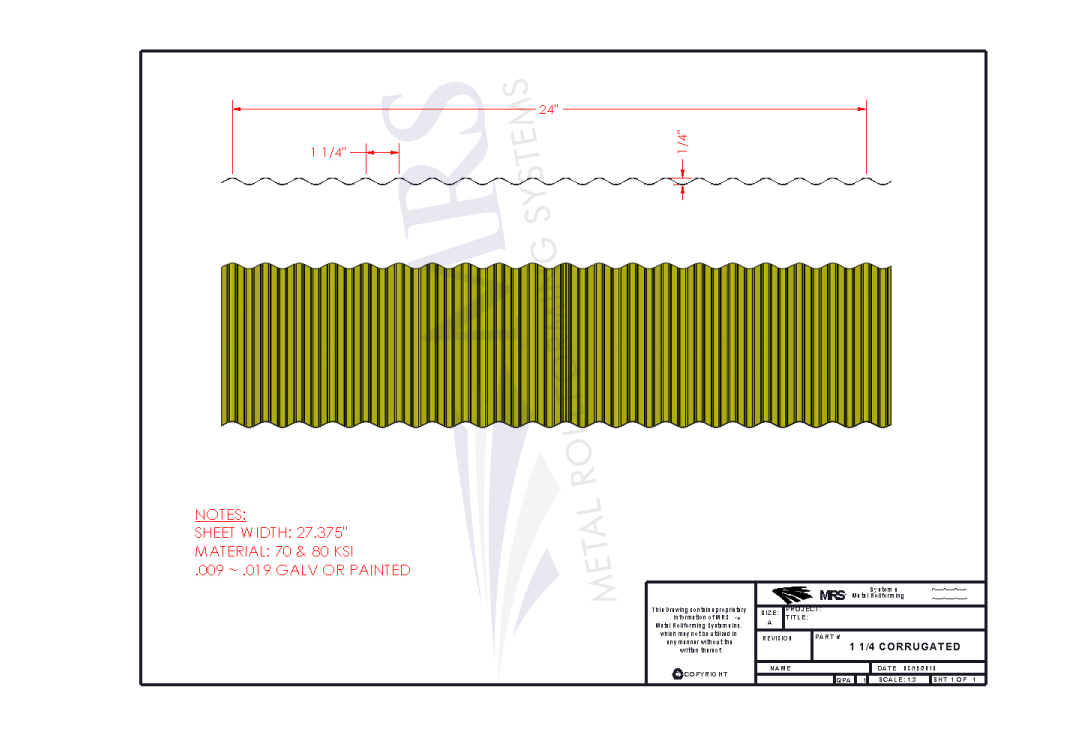

The profiles here are gaining in popularity as architects and designers are looking for new and creative ways to utilize metal panels in their building designs. Nationwide there has also been a resurgence in the corrugated profile as homeowners and builders alike look for that rustic/reclaimed style.

Additional Custom Panel Profiles

Increasingly popular and not to be overlooked are panel profiles that require additional inventory, but which typically carry a much higher margin. When you can step outside of the constraints of standard inventory, truly remarkable and creative things can happen from a panel design perspective.

Advantages of custom panel profiles:

- Material

- Material choice and selection can vary widely, from standard painted product to copper and even bare metal.

- In large portions of the marketplace bare and galvanized are increasingly popular as customers look for that rustic look. Our custom profiles can run numerous gauges (down to 20 gauge), and materials.

- Profiles

- Numerous profiles are available. Custom profiles can be produced and offer great versatility as both wall, roof, and decking panels.

- Design potential

- Work with local and regional architects to get your profile spec’d on a project. Offer up new and creative ways to use your profile; horizontal installation, angled installation. Develop a design library of the various materials that can be run.

- Competition, increased barrier to entry

- At the same time you increase your design potential, you also raise the barrier of entry into the business for your competition. No longer can a startup put in a small rollforming outfit with a few color selections of coil and expect to take business away. The more versatile your company is, the harder it will be to compete with.

Stephen S.

“We had already been in business for around 4 years when we decided to make the leap into custom panel profiles. Working closely with Metal Rollforming Systems we decided on the 7/8” corrugated profile in addition to the HR-36 (box rib) profile. While the initial investment in inventory and equipment was substantial the margins on these products are well beyond anything we anticipated. We have seen increased sales across the board and find our market share and size has grown substantially. Our only regret is that we didn’t do it sooner.”

Corrugated panel profiles are becoming increasingly popular both for interior and exterior applications. Corrugated metal can be produced utilizing anywhere from .010” thickness to .040”, 32 gauge to 20 gauge. Coverage can be specified from 24” to 36”.

Some corrugated profiles can even be produced with the standard 40.875” AG material, or the 43” R panel material reducing inventory.

Corrugated and 5v style profiles with 24” of coverage can be produced with light gauge metals 29-32 gauge reducing the cost to a price conscious homeowner.

Larger corrugated profiles can be produced with heavy gauge, 20-24 and offer increased load ratings and span distances.

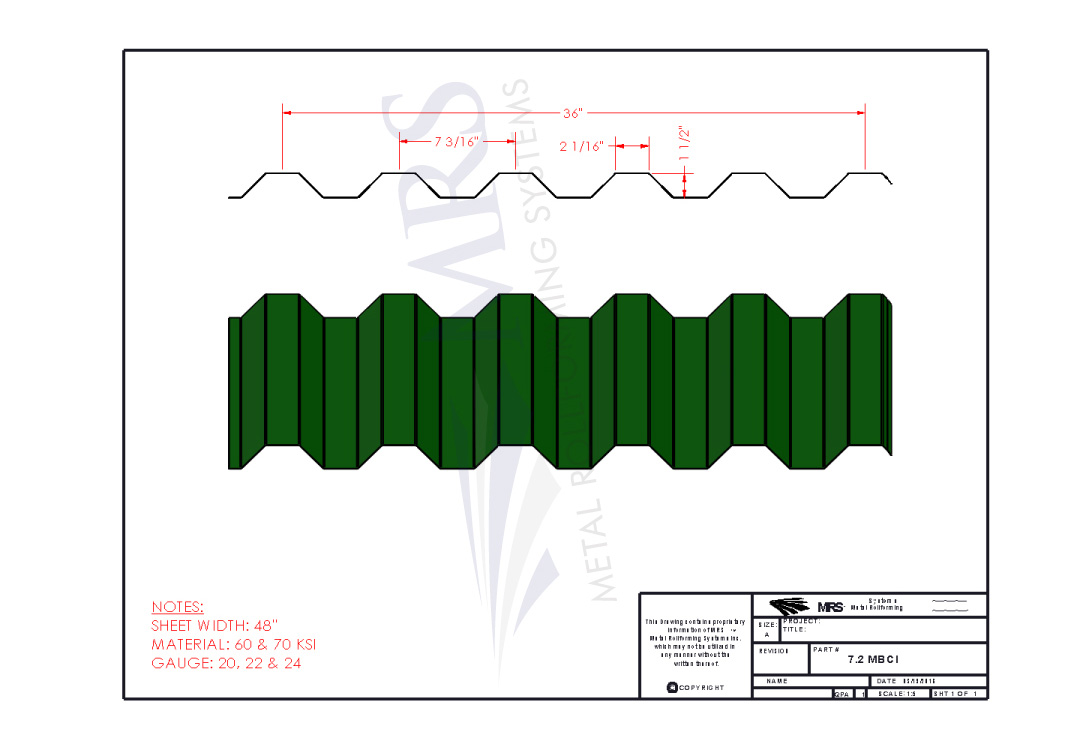

Architectural profiles like those shown here offer a different look from the standard panel profiles. These designs are increasingly popular with commercial buildings and contemporary housing designs.

The HR-36 shown at left is capable of being ran in thicknesses down to 20 gauge making it a versatile panel for sun shades, large span roofing, and even light gauge decking

Add A Deck

In most instances a new profile can be installed on your machine with minimal down time. An MRS tech can have you up and operating again in as little as 1 day. With the cost of adding a second profile less than you may expect, now is a great time to investigate upgrading your existing machine. The profiles shown are just a small sample of what we have to offer. Our team is also well equipped to handle custom profiles should you decide to go that route.

Crated add a deck ready to install at customers facility

Stay Ahead of the Curve

With the fast-paced changes of the industry it is more important than ever to stay ahead of the curve. There is no stagnation in business, either you’re pushing forward or falling behind. Your MRS sales engineer can help you weigh the pros and cons of each of the many options that we offer. Feel free to give us a call at 1-888-284-6794

Recent Comments